Proyecto: Reinforcement of embankment at oil tank farm

Producto: Secugrid® 200/40 R6

Fig. 1 Secugrid PET uniaxial geogrid covered with imported slag fill material as reinforced foundation for oil tank retaining wall

Fig. 1 Secugrid PET uniaxial geogrid covered with imported slag fill material as reinforced foundation for oil tank retaining wall

Challenge:

The new OTMS (Oil Tanking MOGS Saldanha) crude oil storage facility at the deep-water port of Saldanha, situated on the west coast of South Africa, is geographically well located between the Atlantic and the Indian Ocean to allow quick access to the markets in America, Europe

and Asia via global shipping routes.

Once completed, the tank farm will consist of twelve underground crude oil storage tanks, which allow space for a total of 13.2 million barrels of oil. Each tank contains 192 No. of 17m high, continuously cast reinforced concrete columns to support the roof slab. A total quantity of 165,000m3

of concrete was needed during their construction. The total quantity of fill material required was 1,300,000m3. The size of the project equals 24 football fields.

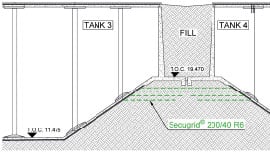

The sides of the tanks consist of 9m high vertical retaining walls that rest on 8m high sloping embankments (Fig. 2). To provide sufficient stability against the slope and -bearing failure under consideration of the high loads resulting from the concrete tank side walls together with the fill between adjacent walls, a safe solution was required to increase the stability of the embankment structures.

Fig. 2 Cross section of secugrid reinforced embarkment with tank concrete retaining wall

Fig. 2 Cross section of secugrid reinforced embarkment with tank concrete retaining wall

Solution:

Slag fill from the nearby Saldanha works iron ore smelter was used in lieu of the original calcrete (carbonated sand gravel mix) to construct the embankments. This resulted in a significant cost saving and was also more sustainable.

A geogrid reinforcement in the upper 2.5m of the embankments was considered in the design to achieve the required safety factors. Four layers of geogrid were incorporated at vertical intervals of 600mm, each with a tie-back length of 7m. A uniaxial laid and welded Secugrid® polyester geogrid with an ultimate tensile strength of 200kN/m in the longitudinal direction was opted for (Fig. 1 and 3).

Because of the slag material’s high abrasiveness due to the angular and often sharp edges of the individual pieces of aggregate, combined with the vibratory forces induced during compaction, an exceptionally robust and high strength geogrid was required to withstand the harsh installation conditions. Secugrid® 200/40 R6 met all these requirements and provided the required long-term design strength in combination with its excellent robustness resulting from the rigid monolithic bars. The use of over 161,000m2 of Secugrid® helped to increase the embankment stability and provided the required bearing capacity for the 9m high vertical concrete retaining oil tank side walls.

Fig. 3 Uniaxial Secugrid geogrid covered with slag material

Fig. 3 Uniaxial Secugrid geogrid covered with slag material